Getting out and about in Dundee!

Last week I headed out to Dundee to tour some more Go Industrial sites, and collect some objects to bring back to lab at AOC Archaeology for conservation. First stop was Verdant Works, where I met with curator Mel Oakley, and conservation intern Kira Nicoll.

Kira, who is currently studying preventive conservation at Northumbria University, is completing a 6-week internship at Verdant Works, where she is researching preventive conservation measures for the working machinery on display there.

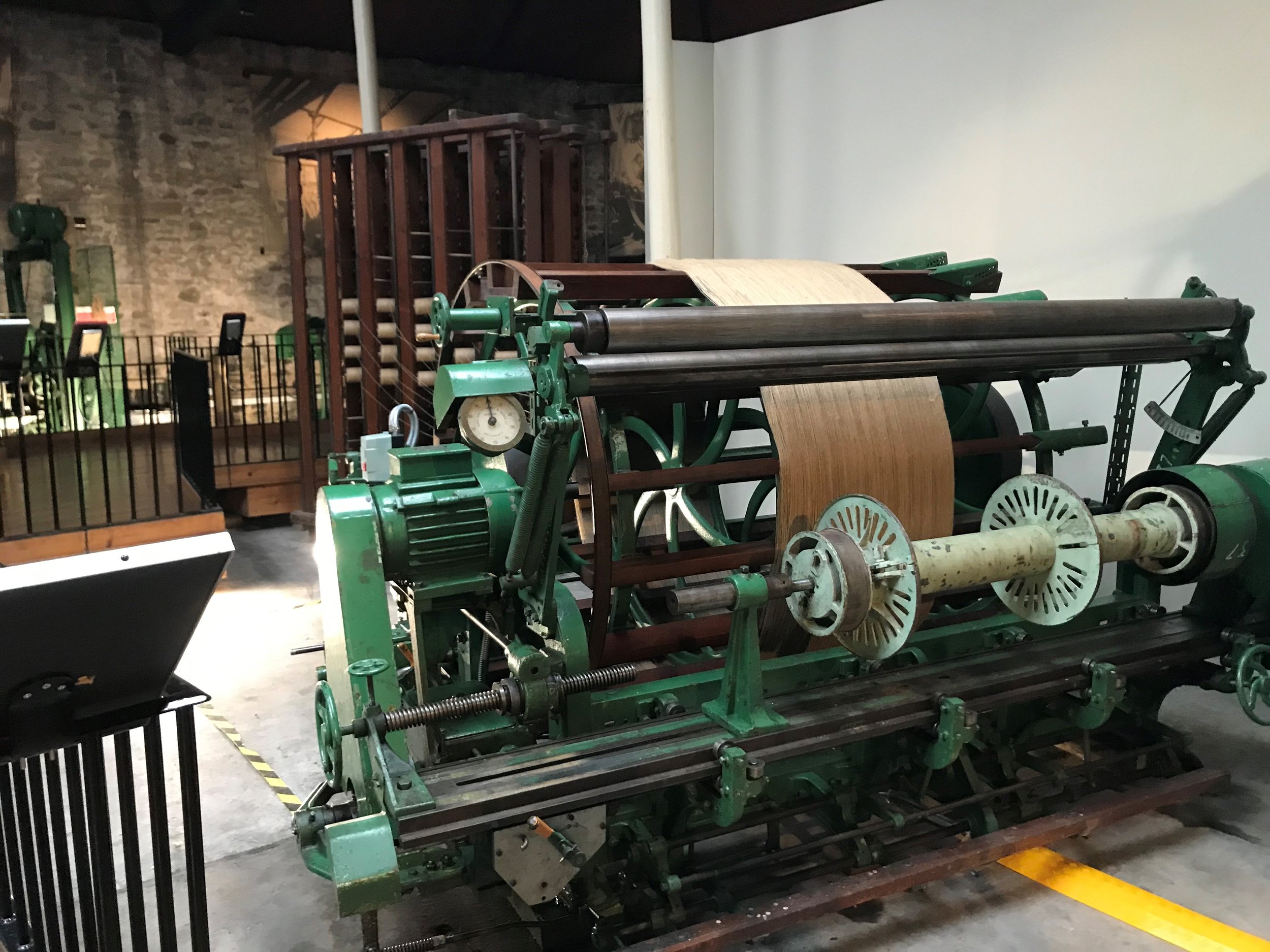

The High Mill at Verdant Works was originally built in 1833 as a flax mill, but by the 1840/50’s it had switched over to processing jute, which was shipped over from India in large pucca bales. Turning this raw jute fibre into a woven textile was a long process, involving nine different machines that were run by the mill workers and powered by steam: by 1864 there were three steam engines at Verdant Works, powering 70 looms and 2,800 spindles! By 1889 however, the mill sadly ceased to produce textiles, and during the 1900’s it was used to deal in scrap metal and to cure rabbit skins.

In 1991, Dundee Heritage bought Verdant Works, and in 1996 the vast majority of the buildings were reopened as a museum, telling the story of Dundee’s industrial textile heritage, with the High Mill being restored and reopened in 2015. One of the highlights of the museum are the machines, which illustrate beautifully the nine-step process that was used to turn raw jute into the finished textile we all recognize today! Several of these machines are still in working order, and curator Mel is working hard to get the others up and running.

During her internship, Kira has been researching preventive conservation measures for these machines, in order to help Mel, keep them in tip top condition! Click below to see videos of these machines in action!

First the jute is batched, then it is put through these rollers (above), which softens the fibers of the jute ..

Next the jute is put into the carding machine (above) which ‘fleeces’ the fibres, and turns it into into a loose fibre called a ‘sliver’. These ‘slivers’ are then put into roving machines (below), which draws them out and adds a slight twist to strengthen the fibre: this is then wound onto a bobbin ready to be transferred to the to the spinning frame.

Once on the spinning frame, the fibres are drawn out to specific weight or thickness, and twisted into one continuous thread; the resulting yarn is then wound onto bobbins (below). After spinning, the yarn moves through the winding department, where the yarn is wound onto spools to create the ‘warp’ threads, and onto ‘cops’ to create the ‘weft’ threads, ready for weaving!

Below are the final machines in the process… from left to right: beaming, weaving & finishing!

To find out more about this fascinating process, or to find out more about Verdant Works, follow the link below!

My next visit was to the HMS Unicorn, moored in Dundee’s Victoria Dock, where Museum Director Matthew Moran gave me a tour of the ship and explained the interesting story behind the oldest, most original ship in the world, and the oldest in Scotland!

Built in 1824 as a Georgian fighting frigate, the Unicorn combines the traditional wooden shipbuilding craftsmanship of the 18th Century with the emerging iron technology of the Industrial Revolution. In 1873 it arrived in Dundee where it was converted into a drill ship for Dundee’s naval reserves, and during the First and Second World War it served as naval headquarters and as a recruitment station for the Tay region.

On May 14th 1945, German U-Boat U-2326 surrendered in Dundee, and was brought to the HMS Unicorn, making it the only wooden sailing ship to have ever accepted the surrender of a U-Boat! Following their surrender, the German officers onboard handed over their naval dirks, a type of long bladed thrusting dagger, to Captain WF Keavy RNVR.

Part of the reason for my visit to the HMS Unicorn was to collect these daggers, which are still part of the collection at the HMS Unicorn, and bring them back to the lab at AOC Archaeology for assessment and conservation treatment. The daggers have been kept in good condition, but there is some damage to the metal threading on the portepee, or sword knot, which will require some intricate repair work (see below).

Check back soon to see how we tackle this challenging conservation treatment!

Naval Dirks, surrendered to the HMS Unicorn during the Second World War

If you’d like to learn more about the HMS Unicorn, follow the link below!