3D Replicas of Clachtoll Broch Assemblage

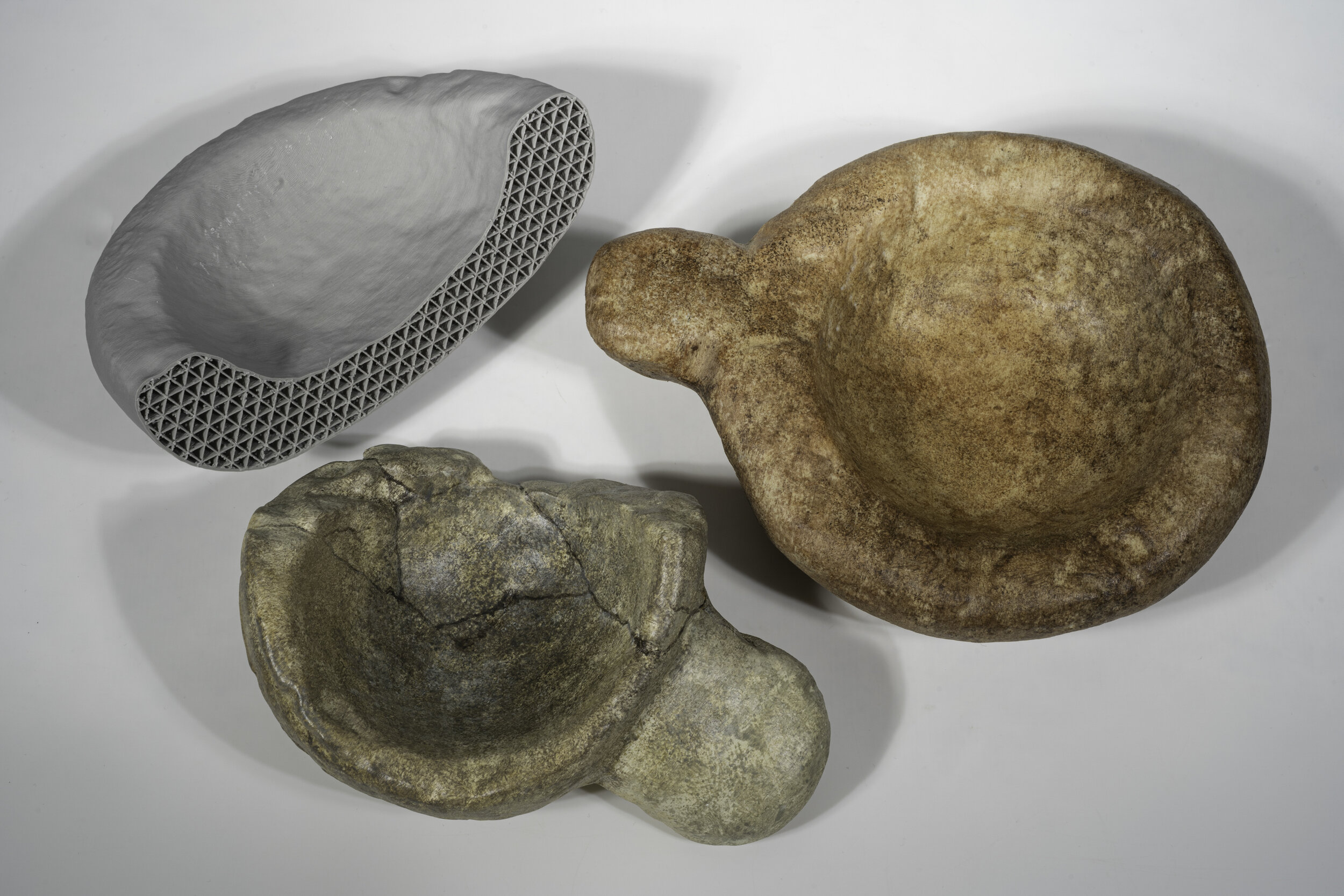

Renders of 3D models from Clachtoll Assemblage | Image: AOC Archaeology

AOC Archaeology in partnership with Historic Assynt has been involved in excavation and conservation of Clachtoll Broch and the associated finds since 2017. During archaeological works at Clachtoll, an abundance of the material was discovered, revealing artefacts not seen by the human eye for over two millennia!

AOC’s post-excavation and conservation teams have been working on interpretation and analysis of this assemblage (you can read more about this here), identifying individual objects and shedding the light on the stories behind them.

During one of the final stages of the project, AOC’s digital heritage team worked on 3D documentation and replication of the selection of artefacts. A range of objects – from pottery and stone to bone, were selected for high-resolution 3D recording. Using photogrammetry, we were able to create digital replicas of objects excavated at Clachtoll Broch, which can be viewed in the gallery below, or directly in our Sketchfab collection.

Digital recording has been used in archaeology for a while, but with development in technology, possibilities for augmenting archaeological processes with digital tools have advanced. Finds specialists and conservators can now analyse high-accuracy 3D models and use this digital record as a non-invasive method facilitating understanding of artefacts’ condition and their past. Interactive 3D models can be published online, and with a layer of storytelling, used for outreach purposes.

A new area that AOC is exploring is 3D printing: the tactile appeal of a 3D printed artefact can enable visitors to develop a more personal connection with places and history – they are experiencing the past through artefacts which they wouldn’t be able to touch otherwise. Another side of 3D printing technology, especially in recent years, is making heritage more inclusive and accessible for people with visual impairments – dedicated handling kits are gaining more popularity across cultural institutions in the UK and beyond!

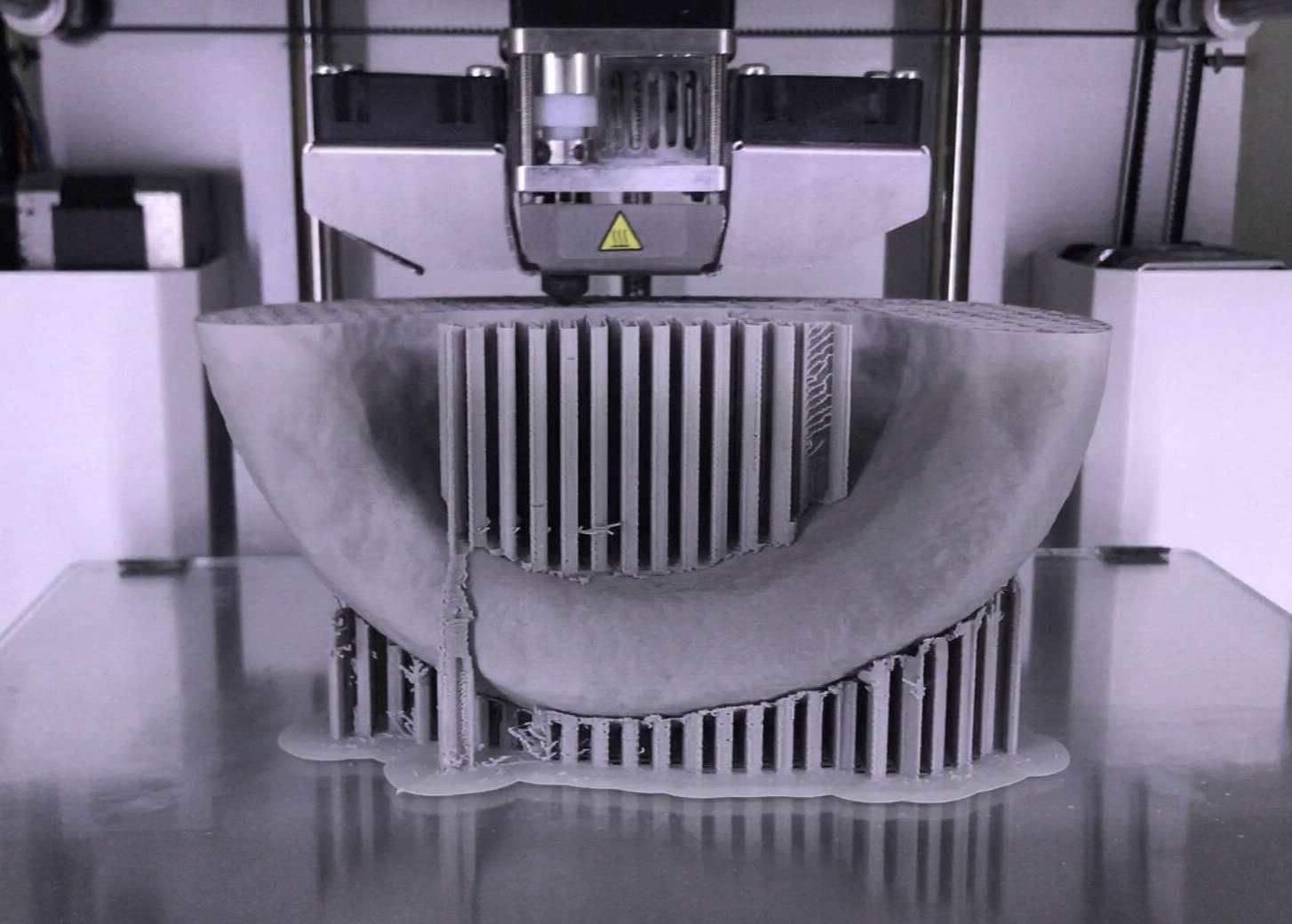

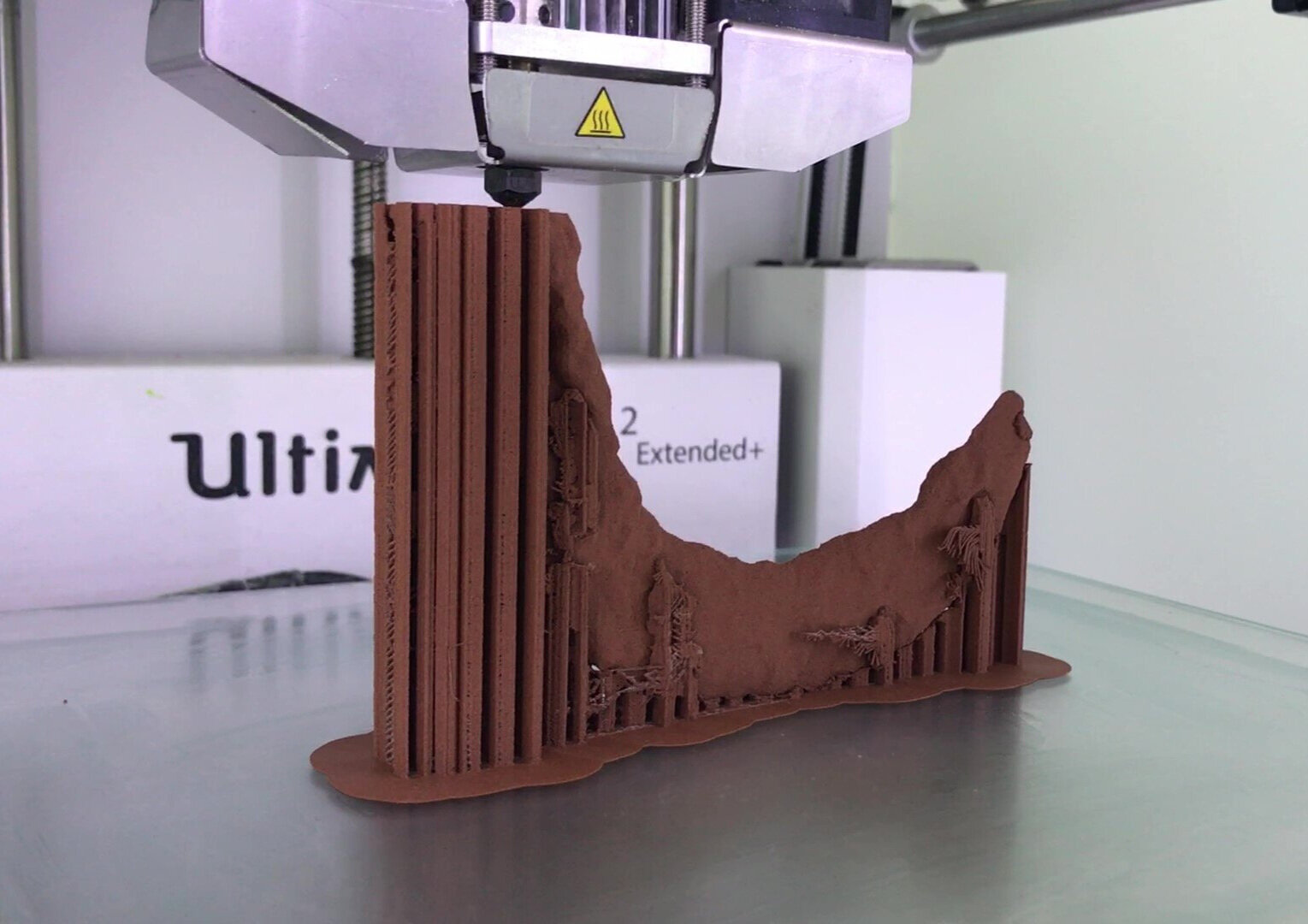

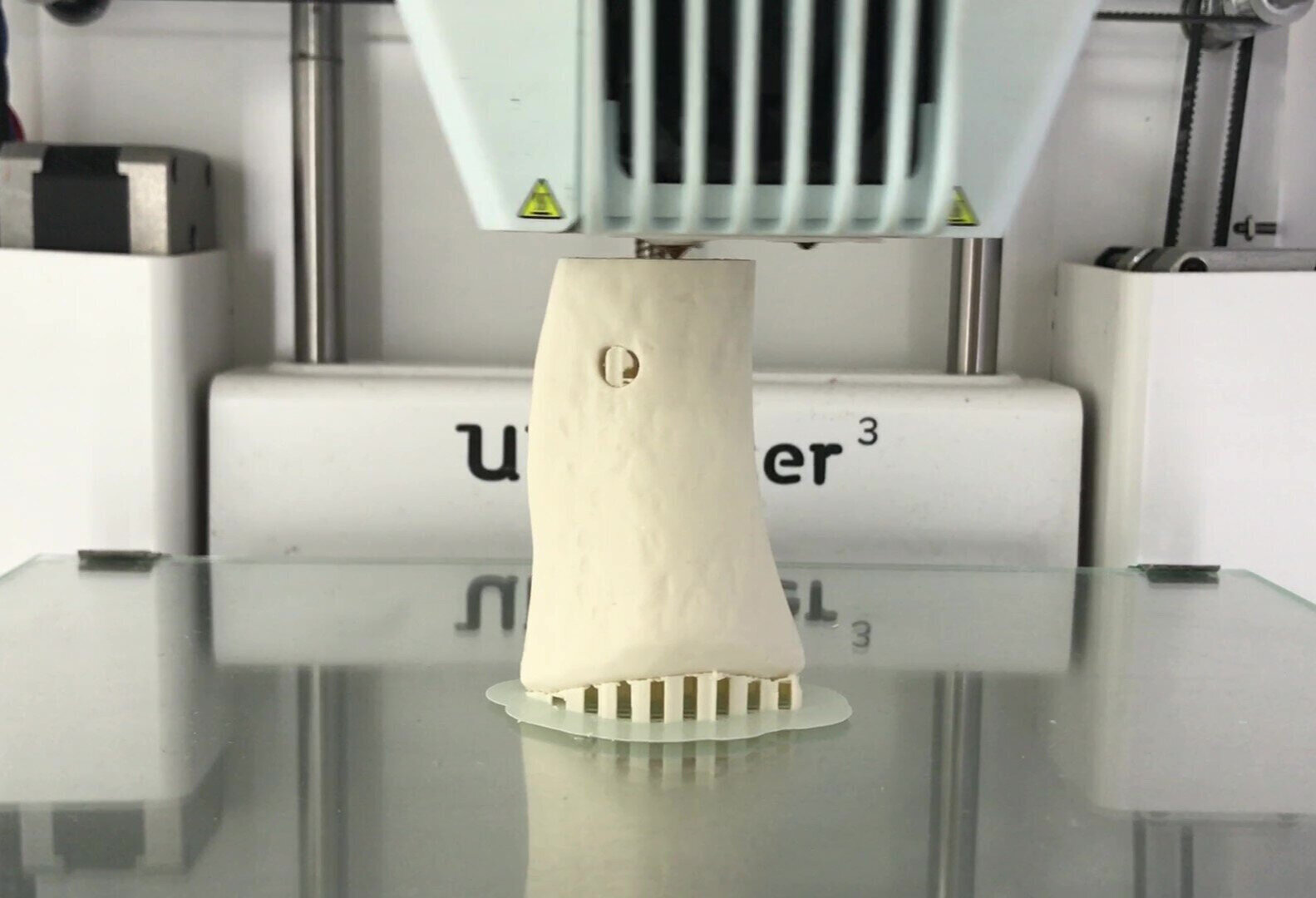

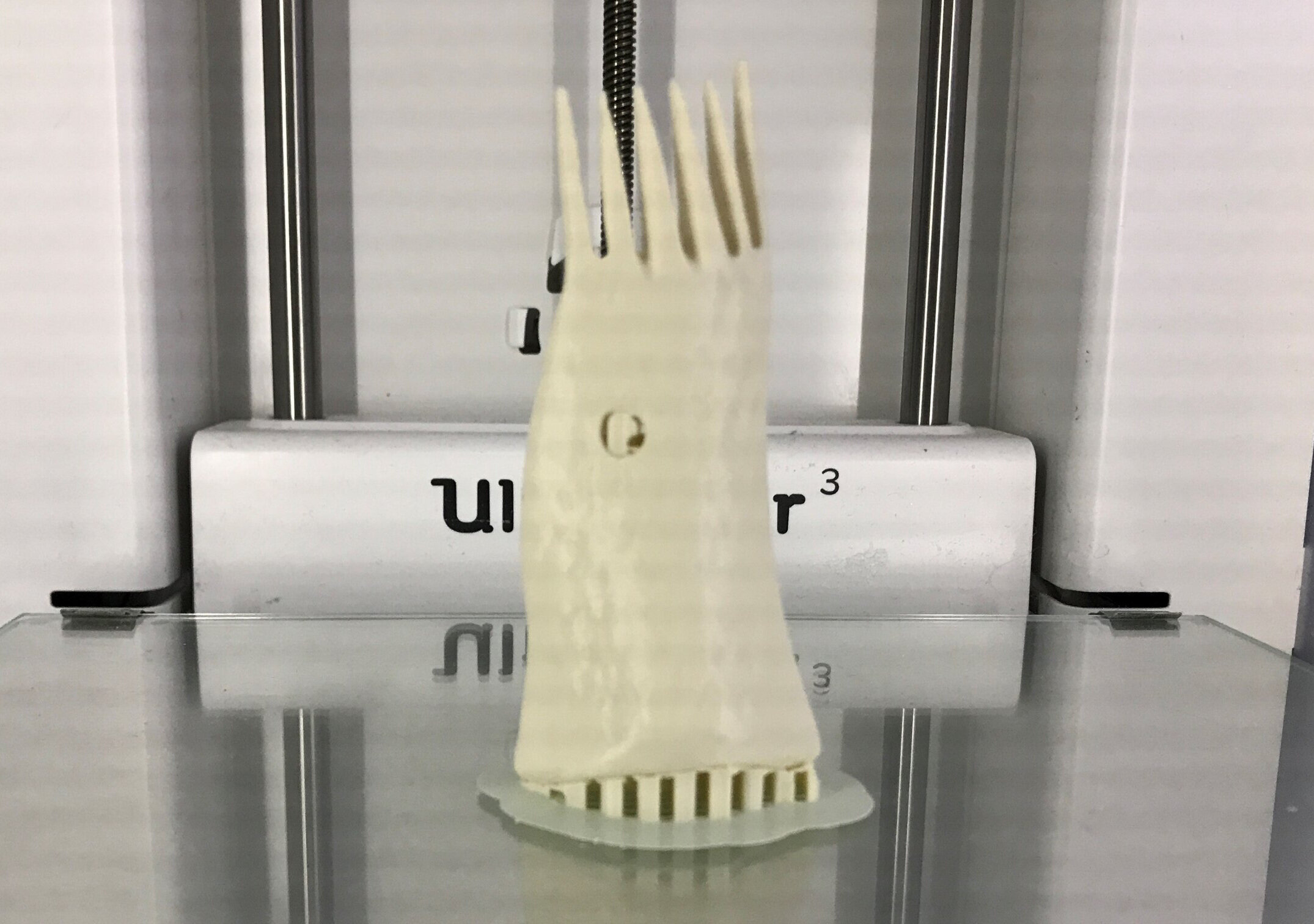

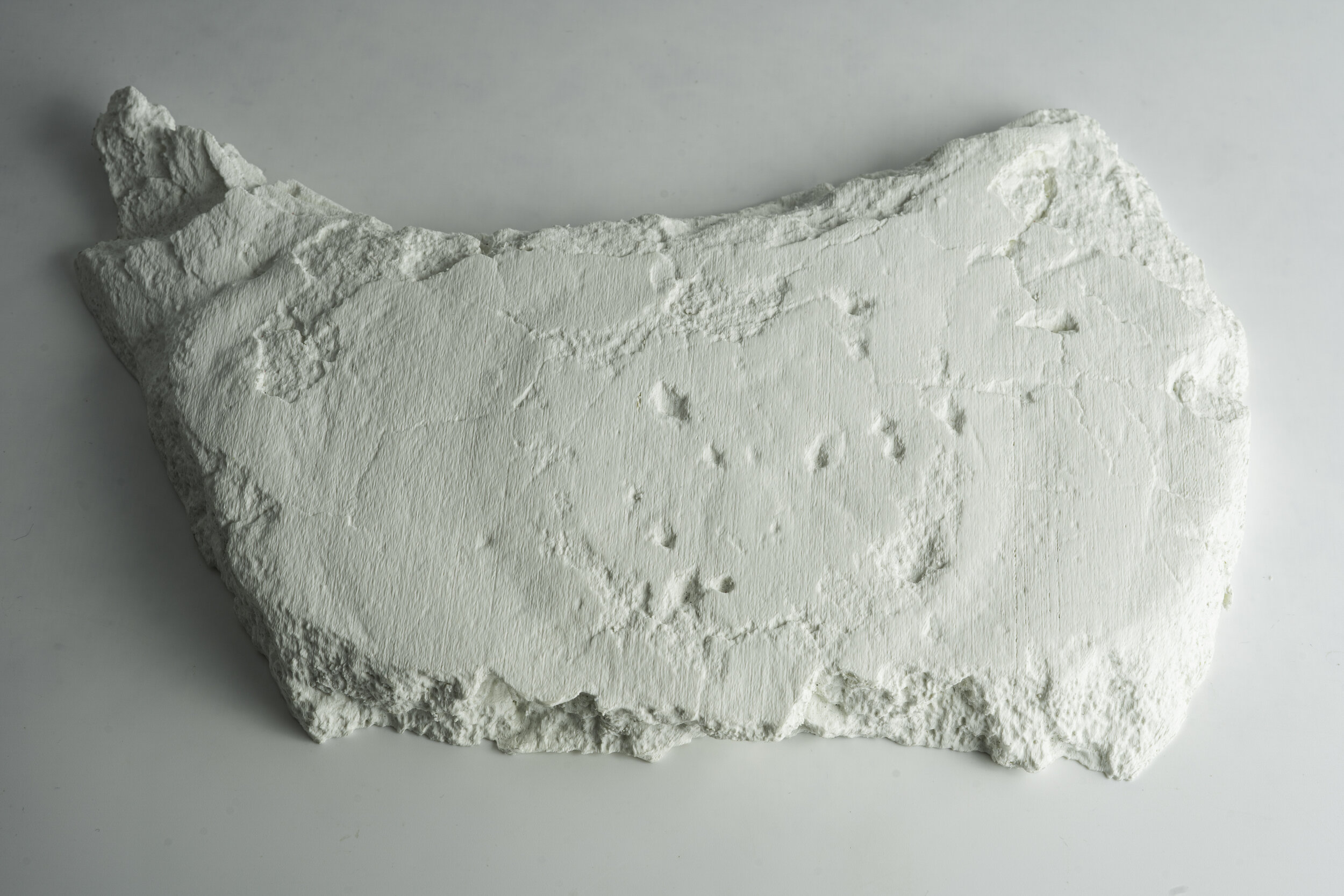

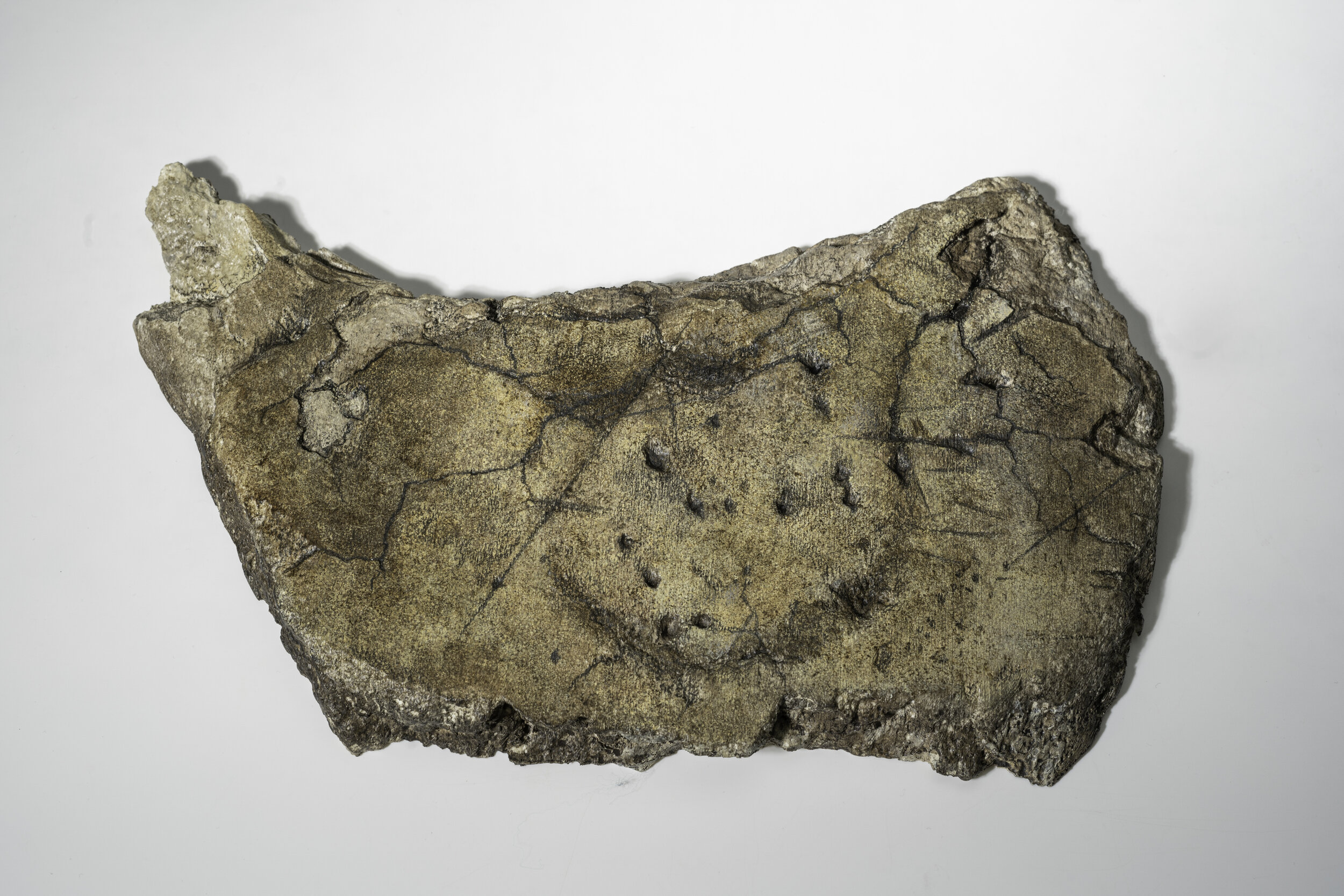

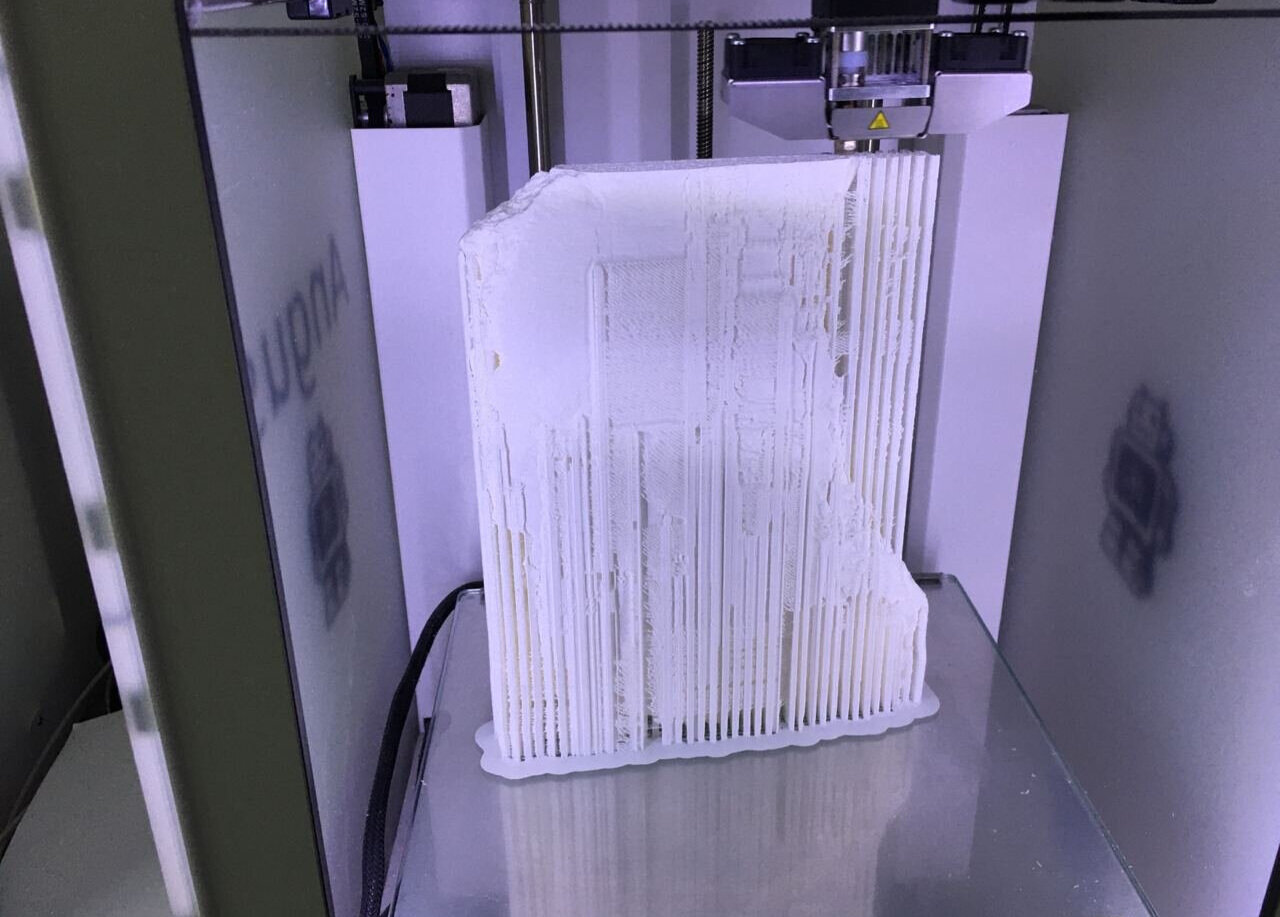

Working with Barclays Eagle Labs at CodeBase in Edinburgh, we printed several artefacts. Ana Aranda (Eagle Labs Engineer in Edinburgh) advised our team on the best materials for this purpose. We decided to use biodegradable Polylactic Acid (PLA) filaments infused with stone, metal or ceramic powder. These composites are heavier than standard PLA, providing a more tactile feel while handling. The ‘raw’ 3D prints were then finished and painted by hand, to imitate the look of the original artefacts.

The results, along with images of the Iron Age objects and photographs taken during the printing process, are presented in the gallery below: